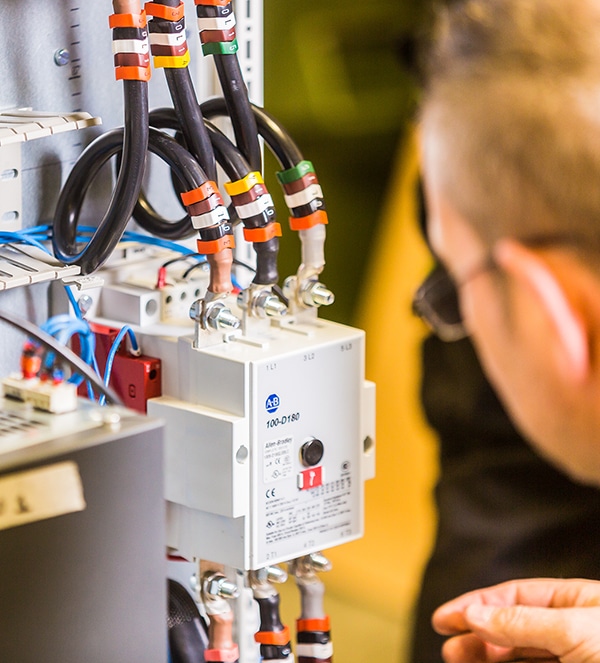

Control Panels and Motor Control Centres

Born from a passion for designing and building quality control panels and MCC’s over 40 years ago.

As a global provider, from design to commissioning, we offer unparalleled high-quality, bespoke control systems, manufactured to all relevant standards.

Halcyon Drives are specialists in variable speed drive and custom-built control panel systems for a wide range of industrial process control and automation projects to customer specific requirements. Control panels can be manufactured to EN60439-1 Form 1,2,3 & 4.

Our panels can range from simple operator consoles or starters to complex PLC controlled networked systems, for a wide variety of industrial applications. Our state-of-the-art modern factory is located in Leeds suitable for offering service and support throughout the UK.

Automation applications and solutions are based on European harmonised standards and technical specifications to meet design, control and safety criteria. All schematics are produced utilising AutoCAD software. At Halcyon Drives, all components are selected from international main source suppliers, whose own accredited standards of design & manufacture meet the most stringent life tests for real world situations.

With our wealth of experience in Power Transmission, we can offer the total solution supplying the full package from the Control Panel, to the Motor and final drive to the driven machine shaft.